.jpg)

TECHNOLOGY

Modern manufacturing methods combined with engineering

open up new possibilities for turbines in model airplanes and drones.

Get insights into our methods at Frank Turbine.

Modern manufacturing methods combined with engineering

open up new possibilities for turbines in model airplanes and drones.

Get insights into our methods at Frank Turbine.

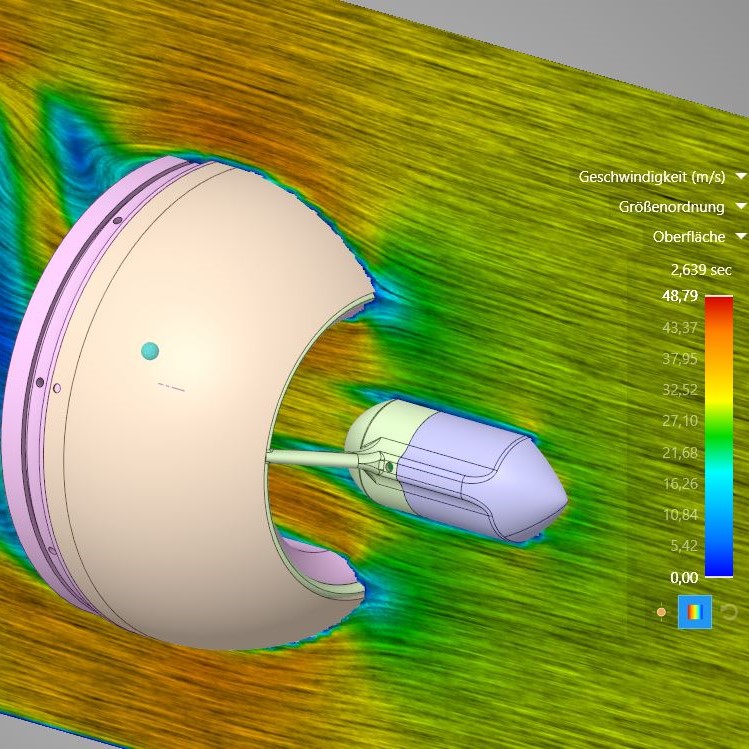

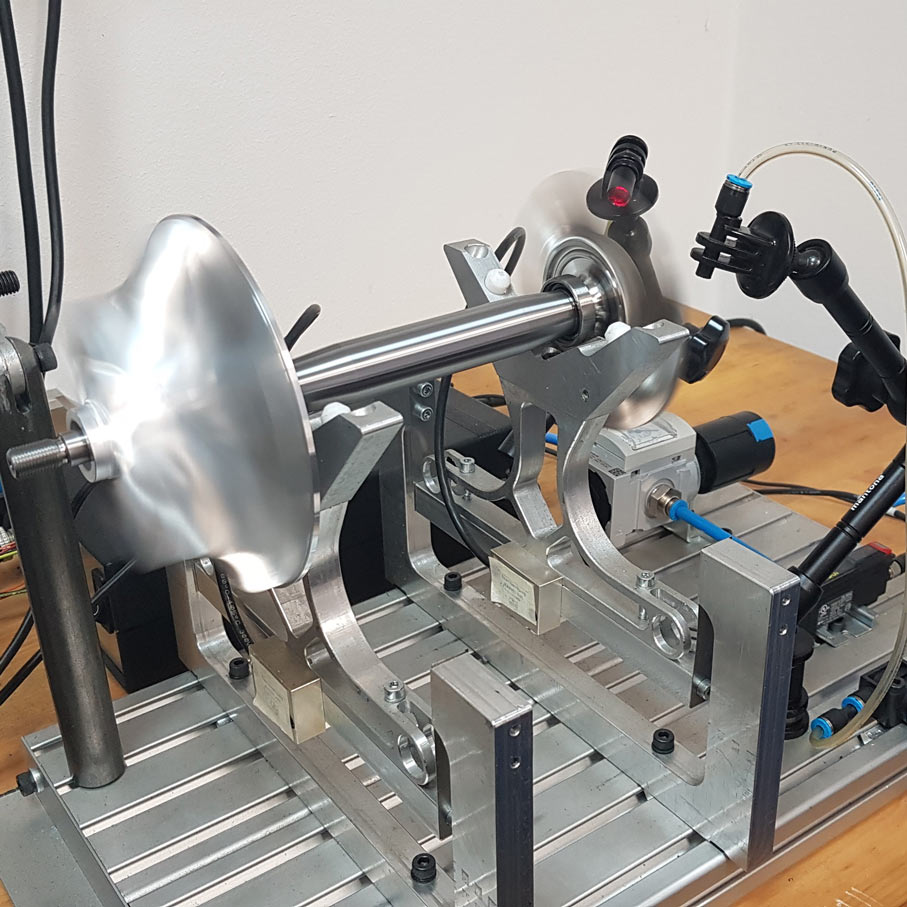

All components are manufactured on state-of-the-art CNC machining centers and assembled in our workshop. The latest CFD simulation models allow us to better analyze the flows inside and outside the engines. These insights are incorporated into our new and further developments of the engines.

The materials used in our engines are exclusively aluminum 7075, chromium-nickel-based alloys, heat-treated steels, and carbon fiber composite materials. No plastic injection molded parts or aluminum cast components are used. All parts are milled or turned from solid material.

Each engine undergoes a series of test runs before delivery and must pass them all within the defined limits. Original Frank Turbine spare parts are always kept in stock for all engines, regardless of the year of manufacture.

We stand for quality, performance, and reliability. See for yourself and visit our YouTube channel, where you will find numerous videos of our manufacturing or function tests.